Strength Durability Furniture Test Equipment TNJ 002-For Table and Bed-Manufacturer

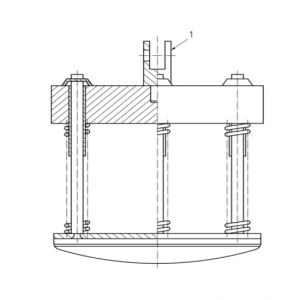

Strength Durability Furniture Test Equipment TNJ 002

Strength Durability Furniture Test Equipment is used for testing the mechanical properties of tables , desks ,beds and chairs.

It Can perform the horizontal static load ,vertical static load, impact test and durability test

Technical specifications

Electrical parameter | Name | Function | Brand | Detailed parameters |

PLC | Programmable controller | Siemens | ||

4ADmodule /4DAmodule | Digital analog conversion input/output | Siemens | ||

Control system | Perform automatic control procedures | HUST TONY | ||

Force sensor | Real-time detection of force values | Hualan Sea | High-precision force sensor that collects force signals in real time | |

Computer | Monitoring and parameter setting | association | ||

Load the cylinder | Provides load force | AirTAC | Bore * stroke 50mm*400mm(5PCS)80mm*400mm(1PCS) | |

Cylinder magnetic switch | Provides limit protection | AirTAC | ||

Proportional valves | Control the cylinder output pressure | SMC | ||

muffler | Eliminates the noise of the cylinder exhaust | SMC | ||

Encoder displacement | Accuracy± 0.5mm | |||

counter | 0~999999 times can be set | |||

Product parameter | Instrument size(Long * wide * high)mm | 2490*2490*2000mm(It can be customized according to customer requirements or product size) | ||

Measurable sample size / minimum, max | Measurable dimensions of the table, durability test (Measurable Dimensions): Longest:1900mm highest:1800mm ; Widest:1900mm Minimum length and width:500mmx500mm Minimum height:400mm Can be customized according to customer requirements Table Impact Test (Measurable Dimensions): Longest:1900mm ; Widest:1900mm Highest:1800mm ; Minimum height:1200mm Minimum length and width:500mmx500mm Can be customized according to customer requirements Cabinet test (measureable size): Highest:2000mm ; Longest:2000mm Widest:1800mm Can be customized according to customer requirements | |||

source | AC 220V 10A 50Hz | |||

air supply | 6kgf/cm^2or above stable air source | |||

weight | about:1200kg | |||

package | wooden case | |||

Transportation requirements | Due to its large size, this device needs to be disassembled and transported and reassembled at the point of use | |||

Max Capacity | Maximum vertical horizontal: 3000N The maximum force level : 1000N | |||

Loading cylinders | Four horizontal and One Vertical | |||

Loading force value (Max) on the theory | 1500Nþ Force value induction: high-precision power sensor | |||

Applied standards: | BS EN 1730: 2012 6.2 Horizontal Static Load Test ISO 7170-2021 6.4 Strength of the structure 6.4.1 Test for structure, underframe and/or legs (Other test standards can be made according to customer requirements) | |||

Control way | PLC control | |||

Air source | Air supply input is 0.4Mpa-0.8Mpa. (6kgf/cm^2 or above, supplied by customer themselves) | |||

Our furniture instrument competitive features

- 1.High-resolution digital controller; closed-loop control. The output end of the cylinder is equipped with a fatigue-grade tension and pressure sensor, and the air pressure control of the cylinder is controlled by an imported SMC gas-electric proportional valve, which can input and control the output force of the cylinder through the computer host interface; realize high-precision testing.

- 2.With real-time force-time curve display.

- 3.The frame structure design is adopted, and the frame is made of custom-made thickened aluminum profiles. Europe standard aluminum profile(Thickness and strength 5 times higher than industry).The structure is stable and beautiful. All cylinder groups are moved by sliding, which can be operated by one person without any tool assistance. The frame adjustment part adopts pulley structure and guide rail plus bearing design, which can easily and conveniently adjust the loading position to adapt to different specifications of samples and improve work efficiency.

- 4.The fixed block at the bottom and the portable magnet can adjust the position at will to adapt tosamples of different specifications

- 5.The loading pad is detachable, which can be easily replaced with different loading pads to meet different test requirements

- 6.Can test multiple samples at the same time, more efficient and energy-saving to complete the testrequirements .Various test items can be realized by moving the combined cylinder combination unit. All channels can be set to independent or joint action mode, and all channels are set with independent setting boxes.

- 7.The PLC controller is used to control the movement of the instrument, and the operation is intuitive and simple. The force value adjustment uses a precision SMC proportional valve to adjust the airpressure to change the loading force value.

- 8.Equipped with a high-precision force sensor to sense the force value instantly, each loading group is individually adjusted and controlled, and the loading force value is stable and reliable.

- 9.After a sudden power failure or artificial shutdown, turn on the power again or restart it, and continue to run according to the parameters set before the power failure, so as to ensure the continuity and stability of the test and avoid loss of test data.

- 10.The interface is easy to operate and easy to use.

- 11.Our equipment is controlled by computer, mobile phone control, Internet control, and real-time video monitoring

- 12.The operating software comes with a test standard program that meets the requirements, and can be upgraded remotely; the test process can be monitored by no one, and the fault can be automatically alarmed, and the fault can be removed remotely; the remote operation interface of the mobile phone can view the surveillance camera and the safe environment of the laboratory site

- 13.Multifunctional interface control software, which can control and monitor multiple devices.

- 14.The control software needs to save the test data of the instrument to the database, which can permanently save and query the historical test data.

Standards

Test items for tables:

BS EN 1730: 2012 Domestic Furniture – Tables Test Methods for Determination of Strength Durability and Stability

EN 12521-2015

BS EN 1728:2012 etc.

(Other test standards can be made according to customer requirements)

Related Products

-

Furniture Testing Equipment

BIFMA Bag Type Impactor Device TNJ-051-2-Manufacturer-HUST TONY

Rated 0 out of 5Read more -

Furniture Testing Equipment

Seat Impactor Device TNJ-051-1-Furniture Impact Test-HUST TONY

Rated 0 out of 5Read more -

Furniture Testing Equipment

Furniture Testing Machine TNJ-019-Vertical Load Impact Test-Supplier

Rated 0 out of 5Read more -

Furniture Testing Equipment

Bed Comprehensive Tester TNJ-001B-Manufacturer-HUST TONY

Rated 0 out of 5Read more -

Furniture Testing Equipment

Furniture Comprehensive Testing Equipment TNJ-001-Desk ,Chair,Bed,Cabinet-Manufacturer

Rated 0 out of 5Read more -

Furniture Testing Equipment

Chair Drop Impact Tester TNJ-051-Furniture Drop Testing-Supplier-HUST TONY

Rated 0 out of 5Read more -

Furniture Testing Equipment

Furniture Comprehensive Test Machine-For Tables And Chairs TNJ-002B-China Direct Factory

Rated 0 out of 5Read more -

Furniture Testing Equipment

Cupboard Door Hinge Durability Tester TNJ-026-Supplier-HUST TONY

Rated 0 out of 5Read more