Toy Safety Test: Compression Test.

Toy Safety Test: Compression Test.

Toy safety is a top priority for parents and manufacturers.In this article, Hust Tony Instruments will continue to lead the discussion on the safety of toys, identify potential hazards in toys, and provide more safety products to the market.

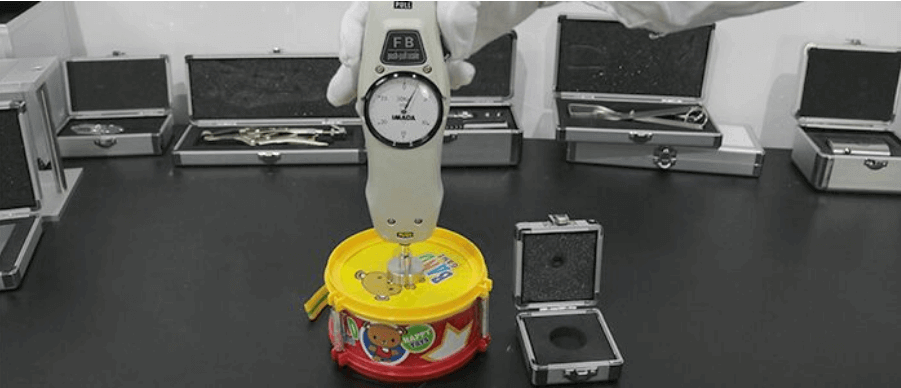

Today we introduce toy safety testing: compression testing.

Compression test program:Place the toy on a horizontal rigid plane so that the parts are tested at the top.A rigid metal indenter with a diameter of 30 mm ± 1.5 mm is applied to the measuring area at 110 N ± 5 N for 5 seconds.

Judging Criteria:Toys designed for small children who cannot sit up alone should not break, and it is acceptable if the cracks do not cause obvious damage.Toys designed for children under 3 years of age should not produce small parts, accessible sharp points and sharp edges.Masks and helmets should not expose pointed flaps, edges, or loose material that may enter the eyes.

EN71 Standard Pressure Head TW-246B – Used to provide stress tests for toy aircraft

According to the standard requirements, during the drop test or tipping test, all accessible areas that cannot be smoothly touched on the toy surface shall be subjected to compression test.

Standard:EN 71-1,ISO 8124-1,GB 6675-2

ASTM Compression Test Disc Standard: ASTM F963, 16 CFR 1500