What Role do Tensile Testing Machines Play In Industrial Production?

What is the function of the tensile testing machine?

With the continuous development of science and technology, tensile testing machines play an increasingly important role in industrial production.

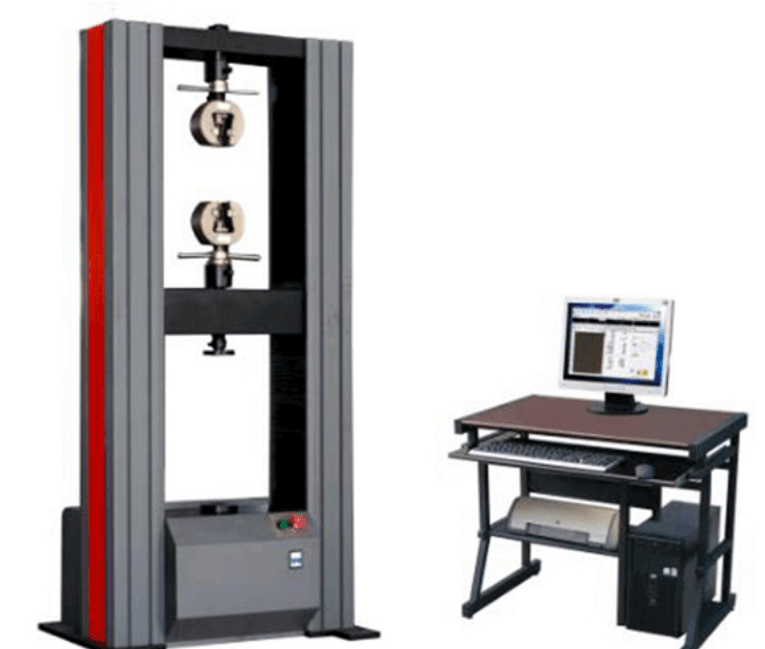

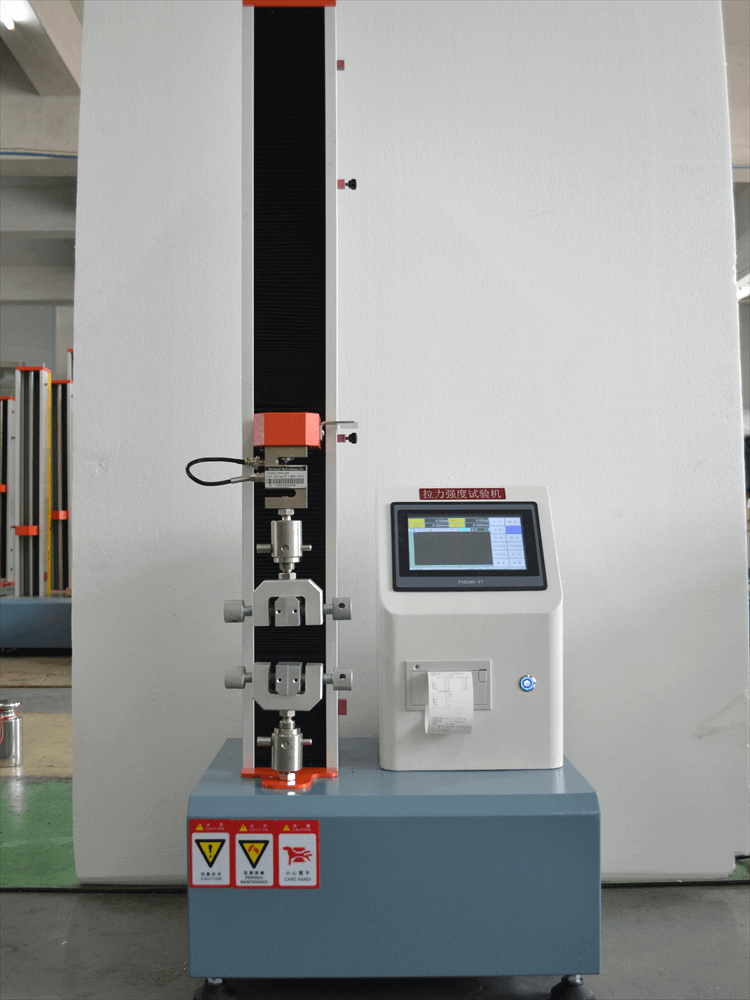

Tensile testing machine is a kind of equipment specially used to test the strength and deformation characteristics of materials under the action of tensile force.

It can be used to test a variety of materials, including metals, plastics, rubber, textiles, and many more.

The main function of tensile testing machines is to test the tensile strength and elongation at break of materials in order to provide strong data support for industrial manufacturing.

Many different test operations and measurements can be implemented

The tensile testing machine adopts an electronic control system, which can realize a variety of different test operations and measurements.

These tests include: tensile, compression, bending, shear, etc.

During the test, the tensile tester records the deformation degree, load, stress, etc. of the material and outputs it to a computer for analysis and processing.

Through such data analysis, we can better understand the performance characteristics of materials.

Tensile testing machines are widely used, including the following fields: manufacturing, automotive industry, construction industry, aerospace, electronic and electrical, medical and health industries.

For example, the automotive industry uses tensile testing machines to test the strength and durability of automotive parts to ensure that automobiles can operate safely under wood-end conditions.

The construction industry uses tensile testing machines to test the strength and toughness of building materials.

It must be maintained and cared for in a standardized manner

In order to ensure that the tensile testing machine has high precision and high reliability, it must be maintained and maintained in a standardized manner.

This includes daily cleaning, regular calibration and inspection, etc.

As long as the tensile testing machine is used and maintained correctly, it can ensure the accuracy and reliability of testing, provide reliable data support for industrial production, and thus promote the development of the industry.