AATCC 201 Fabric Drying Rate Test

AATCC 201 Fabric Drying Rate Test

The heating plate method is a common method of AATCC 201 fabric drying rate test test, this test method determines the drying rate of the fabric water, in contact with the heating plate set at 37 ° C, the surface temperature of the human skin rises, and the body begins to sweat.

This method is suitable for all kinds of fabrics worn by everyone, including knitted, woven fabrics, nonwovens, and fabrics taken from products.

Drying Rate Tester HTF-036-Heated Plate Method-AATCC 201-Supplier

Test Limitations

1.This test is carried out under controlled laboratory temperature and relative temperature humidity conditions.Although the test can be performed under other conditions, in order to compare the results, the same conditions must be used.

2.This test is measured with the same water.If the water reaches the edge of the sample, then it is necessary to increase the specimen size and repeat the test with a new specimen.Further, when comparing results, the same amount of water must be tested for testing.

3.The drying speed of the fabric can test the film in its structure, as long as it is moisturized using this method, the air permeability of the fabric is greater than 5,000 grams / square meter / day, and the detection of water evaporation multi-layer composite fabric can also be tested using this method.

4.When testing the fabric in socks, the socks should be opened and part of the inner socks with a contact heating plate, simulating contact with the fabric and human skin.

Instrument Material

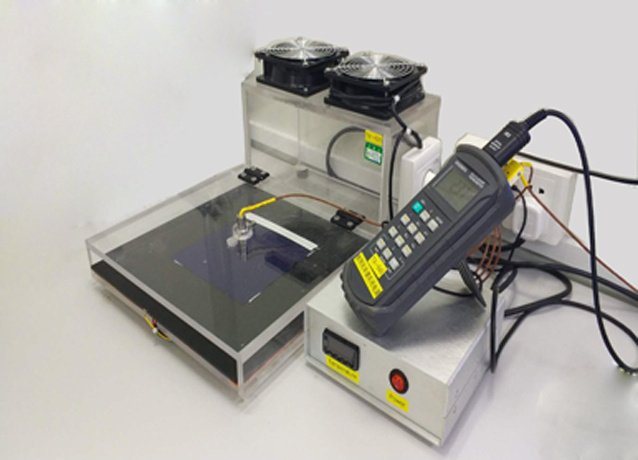

1.Drying rate test device (see figure).

2.Temperature logger – with the function of reading data every 1 second, storage, and transfer to computer data file.

3.Infrared thermocouple probe – temperature range is 15-50±0.1°C.

4.Fan box – output 1.5±0.5m/s air flow overheated width plate, measure thermocouple probe directly behind IR.

5.Metal plate – 30.5× 30.5±0.5cm.6.6 flexible heater – 30.5×30.5±12.5px with the controller to maintain the temperature 37±1°C.

6.Cork board insulation – 30.5×30.5±0.5 cm.

7.Micropipette with adjustable volume, 0.100-1.000±0.003 mL.

8.Anemometer – hot wire type, capable of measuring air flow from 0.5-2.5±0.1 m/s.

9.Magnetic, plastic or metal strip, length 15.0 cm, width 4.0±2.0 cm, 0.2±0.1 cm thick, can be used to fix the specimen in place.

10.Deionized or distilled water.

Test Sample

1.Cut three specimens (15.0×15.0±0.5 cm) from each fabric sample from the right, middle, and left side positions of the entire area for each sample width tested.

2.If testing clothing or final product, take specimen clothing from different parts, i.e. sleeve, back and front.

3.If testing socks or socks, cut the specimen longitudinally and test each unique structure.

Test Adjustment:

1.Prior to testing, conditional test samples are tested for textiles in accordance with the standard practice procedures for regulation, and regulation as indicated in ASTM D 1776.

2.Condition samples in the atmosphere for at least 4 h at 21±1 °C (70±2 °F), 65±2% RH, respectively laid each sample on a screen or on a porous shelf air conditioning rack.

3. All tests are carried out in a standard atmosphere for testing purposes.

Test Process:

1.Turn on the temperature controller for flexible heater and fan, and the metal plate temperature is stable at 37±1°C.

2.Using a hot wire anemometer, verify that the airflow on the board is 1.5±0.5 m/s. Directly measure the airflow infrared thermocouple probe at the back.

3.Place the specimen on the metal and place the specimen for 5 minutes to equilibrate to the metal plate temperature.It is related to one side of the specimen, placed next to the skin and against the surface of the metal plate.Use a peel to secure the top edge of the specimen, closest to the metal plate face of the fan.

4.Place the infrared thermocouple probe 1.0 ± 0.1 cm above the sample in the middle of the sample.It is advantageous to have a marker on the metal plate with the field of view of the IR as the center of the thermocouple probe.

5.Start the recorder, lift the free-end specimen (opposite side magnetic stripe) and apply 0.200±0.003 one milliliter of water on the plate below the sample to probe directly under the infrared thermocouple.Reposition the specimen so that it repositions the specimen covered with water droplets.The start time is the time the specimen is exposed to water.

6.Review the sample to determine the wicking profile produced by water.Confirm that the water does not have the edges of the absorbent.If it is water, then wick to the edge of the sample using a larger sample or reducing the volume.

7.Collect and record the temperature every second until the temperature returns to the initial temperature.Repeat the test on the additional specimen.