Introduction to the AATCC 201 Standard and Equipment Analysis

Introduction to the AATCC 201 Standard and Equipment Analysis

The American Association of Textile Dyeists (AATCC) has developed and approved two evaluation methods to test the drying rate of fabrics.

At present, sportswear with moisture management characteristics has a large market demand.Both quick-drying and quick-wicking functionality are key features of moisture management fabrics.The drying rate of the fabric is the embodiment of the overall effect of evaporative perspiration.

Slow-drying fabrics can affect comfort for wearers who sweat heavily during intense activity.

The measurement of drying rate has become one of the important methods to study the performance of moisture management fabrics. (HUST TONY INSTRUMENTS recommends AATCC 201 Fabric Drying Rate Tester)

The American Association of Textile Dyeists (AATCC) has developed and approved two evaluation methods to test the drying rate of fabrics.The drying properties of fabrics can be analyzed in the following ways.

AATCC Test Methods 200-2013,The drying rate of textiles under full moisture absorption:Air flow method.

AATCC Test Methods 201-2013,Fabric drying rate: heating plate method.

These new test methods simulate actual wearing conditions under which the fabric is exposed to air and in contact with the skin.

Comparison of drying rate test methods

Test Standards | Air Flow Method AATCC TM 200 | |

Testing Range | This test is used to determine the drying rate of textiles that absorb moisture under air movement | This test is used to determine the drying rate of textile products that absorb a specified amount of water in contact with a heated plate under air movement |

Air Flow Condition | The fabric is fixed to a circular opening device to allow vertical air flow through the fabric | There is a horizontal air flow through the fabric surface on the heated plate |

Heating Plate use | without | Yes, the heating plate is heated to 37 degrees |

Drying Rate Expression | ml/hour | ml/hour |

Experimental principles of AATCC 201:Under constant temperature conditions, the drying rate of textiles that absorb the specified amount of water by contacting the heating plate.

Range of Application

The method applies to all kinds of fabrics worn by everyone, including knitted, woven fabrics, and nonwovens, as well as fabrics.

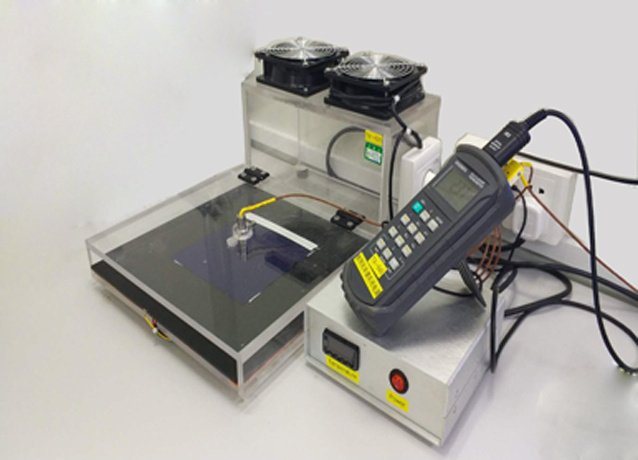

The device mainly contains the following configurations:Temperature loggers, infrared thermocouple probes, fan cases, metal plates, cork board insulation, micropipettes, anemometers, magnetic, plastic or metal strips.Used to hold the specimen in place.

Before the experiment, the room temperature and humidity need to be adjusted to 21±1°C (70±2°F), 65±2%RH.

Equipment water needs deionized water or distilled water, electricity requirements: AC 230V, 50Hz/60Hz

The temperature of the metal plate is stable at 37±1 °C, the air flow is 1.5±0.5 m/s, and the water volume is 1 ml.