What are NSS AASS and CASS In Salt Spray Testing?

What are NSS AASS and CASS In Salt Spray Testing?

Salt spray corrosion is the most common and destructive atmospheric corrosion.

Salt spray test is a kind of environmental test which mainly uses artificial simulated salt spray environmental conditions created by salt spray test equipment to assess the corrosion resistance of products or metal materials.

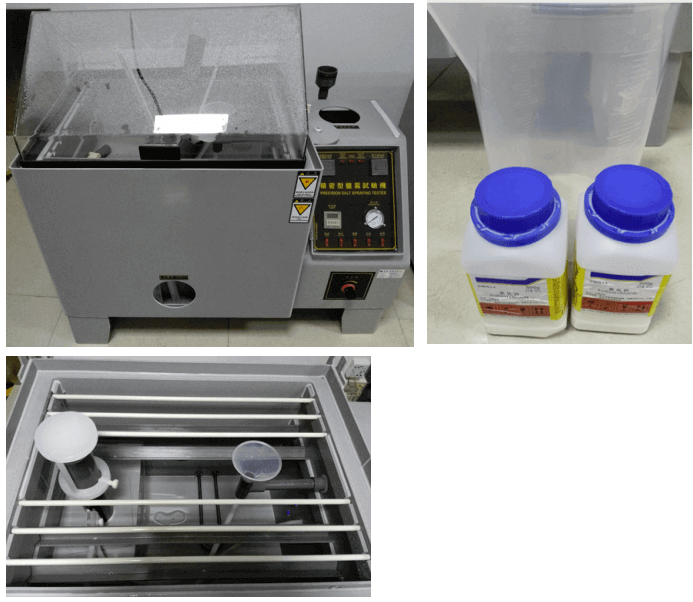

Salt Spray Tester TNJ-025-1-Corrosion Test

The salt zero test is the salt spray test chamber, which uses artificial methods in its volume space to cause a salt zero environment to assess the salt spray corrosion resistance of the product.

Compared with the natural environment, the salt concentration of chloride in the salt zero environment can be several times or dozens of times of the salt zero content of the general natural environment, so that the corrosion rate is greatly improved, and the salt spray test of the product is carried out, and the time to obtain the result is also greatly shortened

For example, if a product sample is tested in a natural exposure environment, it may take 1 year to corrod, and if it is tested in an artificial simulated salt zero environment, similar results can be obtained in as long as 24 hours.

Artificial simulated salt spray test includes neutral salt spray test (NSS) and acetate spray test (AASS). Copper accelerated zero acetate test (CASS).

Definitions of The Three Types of Tests:

1.Neutral Salt Spray Test(NSS)

Neutral salt spray test (NSS) is the basis of salt spray test. Neutral salt spray test is a kind of artificial accelerated corrosion test.

Adjust the pH value of the salt solution prepared according to 1.1, so that it is between 6.5 and 7.2, the pH value can be measured using an acidity meter, as a daily test can also be used to measure the precision of 0.3 pH test paper.The pH of the solution can be adjusted with hydrochloric acid or sodium hydroxide. 24 hours is a period.

The loss of carbon dioxide in the solution when sprayed may cause pH changes.

Measures should be taken, such as heating the solution to more than 35°C before feeding it into the instrument or preparing the solution from new boiling water to reduce the carbon dioxide content in the solution and avoid pH changes.

2.Acetate Spray Test(AASS)

Acetate test (AASS) For plated parts such as cars driving in the urban atmosphere, in order to shorten the test time, acid (acetic acid) is added to the salt solution.

Add an appropriate amount of glacial acetic acid to the salt solution prepared according to 1.1 to ensure that the pH value of the collected liquid in the salt spray box is 3.1-3.3.

As originally prepared, the PH of the solution is directly in the range of 3.0~3.1.

The pH value is determined with an acidity meter, and precision pH test paper with a measurement accuracy of 0.1 can also be used as a daily test.The ph of the solution can be adjusted with glacial acetic acid or sodium hydroxide.

Its corrosion rate is about 3 times faster than the neutral salt zero test.

3.Copper Salt Accelerated Acetate Spray Test(CASS)

Copper salt accelerated acetate spray test (CASS) Through the analysis of the composition of local rainwater and a lot of research on the test acceleration additives, it is found that adding copper oxide to the acetate spray test can greatly increase the corrosion of the medium, and the corrosion characteristics are very similar to the characteristics of serious corrosion in the actual situation, so the CASS test method is further developed.

In the salt solution prepared as above, add copper oxide (CuCI2.2H20) with a concentration of 0.26g/L0.02g/L(i.e. 0.205g/L+0.015g/L anhydrous copper hydride).The pH adjustment method of the solution is the same as that of AASS.

Its corrosion rate is about 8 times that of the neutral salt zero test.

How to select tests?

It is mainly based on the material and coating of the sample.

1.Neutral Salt Spray Test(NSS)

Applicable to metals and their alloys, most metal coatings, metal overcoats (anodic or negative polarity), conversion films, anodic oxide coatings, organic coatings.

2.Acetate Spray Test(AASS)

Suitable for all kinds of inorganic and coated, black and colored gold, such as copper-nickel-chromium coating, nickel-chromium coating, aluminum salt zero test standard anodic oxide film.

3.Copper Salt Accelerated Acetate Spray Test(CASS)

It can be used to test decorative coatings of copper/nickel/chromium or nickel/chromium, and to test anodic coatings on aluminum.

What are the application areas of salt zero test?

Salt zero test is used in aerospace, aviation, shipbuilding, hardware and electronics, electrical appliances, chemical industry, post and telecommunications, automobile and motorcycle, industrial and mining enterprises, electroplating plants, quality inspection and other departments and industries.

It can also be used in the heat treatment surface treatment industry, such as QPQ process plans will require smoke zero experiments, so heat treatment and surface treatment will be used.

Hust Tony’s Salt Spray Tester is made of imported white PVC board, the interior adopts advanced ring production solid reinforcement technology, strong structure, never deformation, and acid base, high temperature resistance and never aging, suitable for neutral salt spray test (NSS), acetate spray test (AASS), copper accelerated acetate spray test (CASS).