Which of the Following Product Properties Does The Box-Type Rain Testing Machine Test?

Which of the Following Product Properties Does The Box-Type Rain Testing Machine Test?

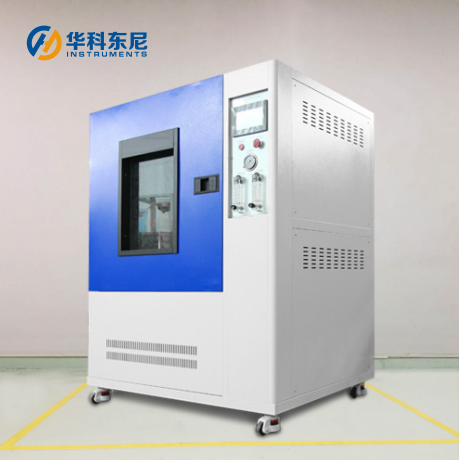

Box type rain test box is also called rain test box, rain waterproof test box, swing pipe rain test box is suitable for all kinds of car parts and electronic appliances and other industrial electronic products of rain dust and dip sand water experiment, car parts include lights, door lock, electrical, appearance, dust jacket, electronic household appliances and other system of full seal stability test.

Test The Following Product Performance:

1.This equipment is used to simulate dynamic operation of experimental data in various intensity rain environment to evaluate the operation quality of the product.

2.The internal test space material is high quality imported stainless steel plate, and the shell is A3 steel plate electrostatic spraying.

3.All other parts that touch water are made of stainless steel or copper.

Specific Specifications:

Model | TW-12 | |

The Size Outside The Water Tank | 1450*1230* 1820 mm (include casters) | |

The Size of The Inner Box | 1000*1000*1000 mm | |

Number of Nozzle | 4 Pcs | |

Angle | 0°、30°、60°、90° | |

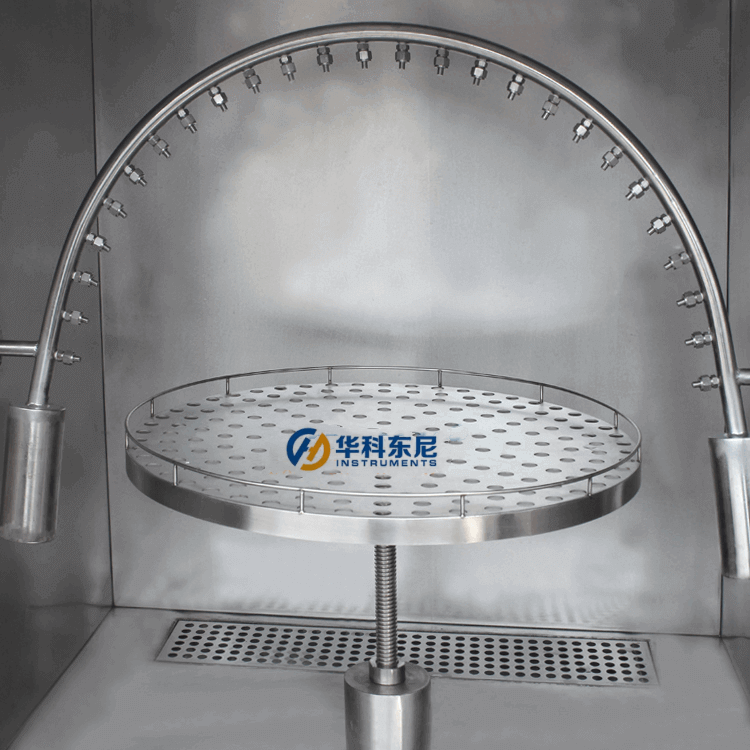

Nozzle Distance | Dia 400 mm ( Manual lift 400-650 mm distance between the turntable and the bottom ) | |

Max Loads Turntable Loads | 50 kg | |

Speed of Turntable Rotates | 1-10 r/min | |

Spray Water Flow | 14-16L/min | |

Water Spray Temperature | 25℃,80土5℃ | |

Spray Pressure | 8000-10000 Kpa | |

Sprinkler Impact | 0.9~1.2N | |

Test Time | 120 S ( 30 S per position, can be set ) | |

This Tester Chamber Voltage | AC380V+10% ;50H+10% ,Three-phase five line system | |

Sample Voltage | 220V.50Hz | |

Power | 18.0 KW ,Fire line+zero line+protective ground line(Resistance<40) | |

Standard Accessories | 1 pcs | 5 meters water pipe |

HUST TONY Rain Equipment Unique Advantages:

1.Rain test box is a kind of artificial imitation of rain test box. It is well known that all components and equipment in the atmospheric pressure environment, regardless of the operation condition or storage condition, will be affected by various water (including impurities) to varying degrees. Rain test is to avoid the change of operation efficiency of these equipment when it is soaked by rain and rain or after rain.

2.The performance indicators of the experimental box meet GB/T10485 “Car and trailer external devices, car and trailer external lighting and signal device basic environment experiment, industrial electronic products basic environment experiment” and JIS, MIL and other related experimental specifications.

ISO 20653-2006, GB-4208-93, GB2423.37-89La, GB4208-93, DIN40050.5K and other corresponding national specifications of the rain test.

3.The shower head is made of stainless steel, evenly distributed on the top of the shower experiment box with aerosol spray; Large rainfall sprinklers are distributed around the experimental box, and the spraying direction is adjustable. The water channel is controlled by the switching solenoid valve. There are flow meters in the spray line to show the amount of rain.

4.The original imported inverter is used to show the speed and set speed, and the rotation speed of the turntable is adjustable.

The Following Points Should Be Paid Attention To In Equipment Maintenance:

- If the experiment is not carried out for a long time, the experimental water in the water tank should be drained to keep the experimental tank clean.

- Pipe speed regulator, experimental time, rain time, turntable speed regulator, power switch, rain switch, turntable switch, and rocker switch.

- Temperature protection inside the box to prevent out-of-control temperature control from affecting the experiment, and three-phase voltage phase sequence protection.

The Manufacturer Gives You Thoughtful Guarantee:

Pre-sale: professional technical consultation, providing the best equipment solutions (equipment selection, product experiment plan, laboratory construction plan).

During sale: customer communication, progress notification; equipment related guidance, installation, debugging, test run, etc.; cooperation with calculations.

After-sales: One-year warranty, lifetime protection!

Full Service:

- Technical training: operation and application, daily maintenance, detection and elimination of common faults.

- Regular return visits: inspect equipment, eliminate hidden faults, and deliver new news

- Special storage support for spare parts and spare parts.

- The after-sales service department provides quick response to maintenance services.

- Full-time maintenance personnel ensure timely and effective troubleshooting

Method: 7×24-hour customer service hotline, specially equipped service email