Flooring Radiant Heat Flux Test Apparatus HTB-008-Supplier

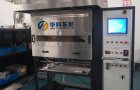

Flooring Radiant Heat Flux Test Apparatus

Flooring Radiant Heat Flux Test Apparatus.Test with a small flame igniting flooring material placed horizontally and exposed to a tilting thermal radiation field. Suitable for a variety of flooring materials. Such as: textile carpets, cork boards, wood planks, rubber boards and plastic floors and floor spraying materials.

The device may react to the burning properties of the flooring material including the substrate used, the backing material, the underlying material or other aspects of the flooring material may affect the test results, which is used to test and describe the combustion characteristics of the flooring material to the fire pair thermal reaction under laboratory control conditions

Technical Specifications

1.The whole machine is composed:It is mainly composed of test equipment, smoke density measurement device, radiation value calibration system, gas control system and data acquisition system, in line with the provisions of GB/T11785-2005 standards

2.structure:

1. It is composed of a calcium silicate plate with a thickness (13±1) mm and a nominal density of 650 kg/m3 and a fireproof glass with a size (110±10) mmx (1100±100) mm, which is a quartz high temperature glass, installed in front of the box so that the progress of the entire specimen and the combustion can be observed through the observation window during the test; A metal protective layer is installed on the outside of the test chamber, and under the observation window, a door can be tightly closed, which allows the specimen platform to be moved in or out; The panels are made of high-quality stainless steel with a thickness of 1.2mm.

2. The test chamber is composed of a sliding platform, which can strictly ensure that the specimen fixture is in a fixed horizontal position, and the total air circulation area between the test chamber and the specimen fixture (0.23±0.03) m2 is evenly distributed on both sides of the long side of the specimen

3.Radiant heat source:

1. It is a fine-pore ceramic hot spoke plate mounted in a metal frame, the outer frame of the radiation plate is made of stainless steel (2.5±0.2) mm, and the radiation plate is made of porous refractory. The radiation area size is (300±10) mmx (450±10) mm, the radiation plate can withstand a high temperature of 900 °C, and the air-gas mixing system through a suitable device to ensure the stability and repeatability of the test, the radiation heating plate is installed above the specimen fixture, and its long side and horizontal angle are (30±1) °C

4.Smoke extraction system:

1. Composition: The combustion gas used for extraction is not directly connected to the box. When the radiant plate is closed and the sample exit is closed at the specified position of the simulated sample, the gas flow rate in the flue of the chamber is (2.5±0.2) M/S

2. Smoke exhaust capacity: The smoke exhaust capacity of the smoke extraction system is (39-85) m3/min at a temperature of 25 ° C

3. The measurement of the flow rate of the smoke exhaust channel and the installation position, the measurement of the flow rate is measured by a digital display anemometer. The accuracy is ±0.1m/s. Mounted on the cabinet flue, the measurement point is just above the lower edge of the cabinet flue (250±10) mm on the centerline

4. Anemometer: imported brand hot film anemometer, measuring range 0-10m/s, smoke exhaust speed (2.5±0.2) m/s

5. Maximum use power: 5KW

6. Timing accuracy: <1s/h

7. Radiant heat flow meter: range: (0-50) kw/m2, accuracy ±0.2Kw/m2, accuracy: <±3%, using the Netherlands HUKSEFLUX high-precision imported Schmidt-Boetter type heat flux meter, measuring end diameter 25mm round foil heat flux meter, calibration radiation flux is (10-15) kW/m2

8. Thermal radiation pyrometer: the use of high-precision digital display radiation pyrometer, for the imported brand. Controls the thermal output of the radiant panel with a range of 400-600 °C, an accuracy of ±0.5 °C, and a constant sensitivity in the range of wavelengths from 1um to 9um

9. Radiant plate (plate gas road) gas flow: the use of high-precision imported brand mass flow controller to adjust the flow, the range of 1.5 ~ 15L / min

10. Radiant panel (specimen road) air flow: the use of high-precision imported brand mass flow controller to adjust the flow, the range of 60 ~ 600L / min

11. Blackbody temperature error: ±5°C

12. Smoke exhaust speed: (2.5±0.2) m/s

13. Smoke exhaust capacity: (39-85) m3/min

14. Porous refractory radiant panel size: 300mm×450mm, can withstand about 900 °C high temperature.

15. Thermocouple: K-type stainless steel armored thermocouple with a diameter of 3.2mm, measuring range: 0-1000 °C

16. Burning blowtorch: outer diameter ¢ 10mm inner diameter ¢ 6mm, 35 ¢ 0.7mm holes on the torch tube.

17. Flame height: 60~120mm adjustable.

18. Ignition system: high voltage electronic ignition.

19. Powerful exhaust system: This machine is equipped with a strong exhaust fan, when the test is completed, start the exhaust fan system to discharge the exhaust gas out of the outdoors.

20. Data acquisition system:1.Includes industrial modules, control systems, computers.2.Analog acquisition module: 12 inputs, acquisition rate of 10 times / s, acquisition bits 16 bits.3.Switching input and output modules: 5 optically isolated passive switch inputs, 5 relay normally open outputs.

Control System and Operation Interface

- The use of instrument and equipment special development software LabelView and data acquisition control card, can display the radiation flux calibration curve, light transmittance curve, box temperature, etc., and comes with ASTM E648 test calibration curve

Control mode: Using the board module I/O board, PID + SSR control mode, the acquisition system can collect and record the radiation flux curve CHF value, HF-10 value, HF-20 value, HF-30 value and record the flame extinguishing time and the distance of flame propagation

Test software: Includes the following features

1.Standard test procedure for radiation flux curves

2.Calibration procedure of the smoke measurement system (flue gas device), including the zeroing and range of the optical system, and the automatic calculation of the drift of the optical system

3.Recording, test and calibration report printing

Output and printing of test reports

One computer

Includes a set of transmittance measurement software to output curves and reports. (See Figure 1 for the graph)

Device structure

1.The structure of this machine is composed of two parts: combustion box and control bo

2.Combustion chamber size: L1420*W1200*H2300(mm)

3.Control box / combustion box / hood material: the use of SUS304 high-quality non-steel plate, CNC machine tool processing molding, arc shape is beautiful and generous

4.Blowtorch: self-made by our company, stainless steel material, fully in line with the requirements of GB/T11785 standard

5.The furnace plate of the radiant high temperature furnace adopts the integral metal type and will not break due to high temperature

6.The cooling system uses water circulation to cool down, and the water tank is made of SUS304 stainless steel material and can be circulated by a water pump

7.Other mechanical parts materials are made of high-quality stainless steel or A3 material thickened plating, anti-corrosion and anti-rust

standard

GB8624-2012 Meet the requirements of “Classification of Combustion Performance of Building Materials and Products”

GB/T11785-2005/(ISO9239-1:2002,IDT)Complied with the “Performance Determination of Combustion of FloorIng Materials – Radiant Heat Source Method”

Related Products

-

Flammability Testing

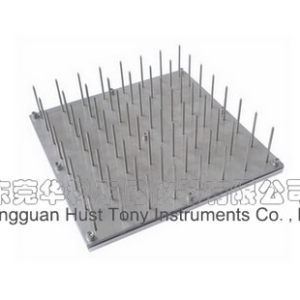

Flammability Testing Nailed Fixture TW-224-Manufacturer-HUST TONY

Rated 0 out of 5Read more -

Fabric flammability tester

Micro-Computer Building Material Non-Combustibility Tester HTB-014

Rated 0 out of 5Read more -

Fabric flammability tester

Flooring Radiant Heat Flux Test Apparatus HTB-008-Supplier

Rated 0 out of 5Read more -

Fabric flammability tester

UL94 Horizontal Vertical Flame tester HTB-066-Supplier-HUST TONY

Rated 0 out of 5Read more -

Fabric flammability tester

UL94 Flammability Test Chamber HTB-066B-Touch Screen-Supplier-HUST TONY

Rated 0 out of 5Read more -

Physical & Mechanical Testing

Laboratory Fume Hoods TY-066-Chemical Exhaust Hood-Supplier

Rated 0 out of 5Read more -

Fabric flammability tester

Glow Wire Test Apparatus HTB-007-Manufacturer-HUST TONY

Rated 0 out of 5Read more