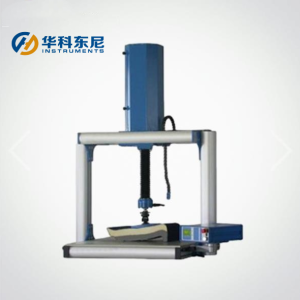

Sofa Durability Testing Machine TNJ-010-Manufacturer-HUST TONY

Sofa Durability Testing Machine TNJ-010

Youtube video : Click here

Technical Specifications

Model | TNJ-010 |

Weigh of Loading Block | 50±5 kg |

Loading Position | 350 mm before Seat surface |

Armrest Loading | Φ50 mm |

Edge of Loading Surface | R 10 mm |

Armrest Loading Position | 80 mm before armrest |

Armrest Loading Direction | 45°according to horizontal direction |

Armrest Loading Force | 250 N |

Backrest Loading | 100 mm* 200 mm |

Backrest Loading Position | The center of two loading parts’ distance is 300 mm , 450 mm height or it is the same level according to the Backrest upward. |

Backrest Loading Force | 300 N |

The Way of Loading | Load alternately |

Testing disc:Φ100 mm | Φ100 mm |

Edge of Testing Surface | R 10 mm |

Testing Speed | 100±20 mm/min |

Weigh | Loading surface Φ350 mm edge :R3,weigh:70±0.5 kg |

Lift way of testing group:Motor drive screw to lift. | Motor drive screw to lift. |

Controller | Touch screen to display. |

Frequency of Testing | 0.33~0.42 Hz(20~25 times/min) |

Air Supply | 7 kgf/cm^2 or more stable air supply |

Size | Host: 152*200*165 cm |

Net Weight | 1350 kg |

Power | Three-phase four-wire 380 V |

Features

1.Novel design, highly integrated, advanced control.

2.The test and measurement items that previously required three machines can be completed with one instrument, and the advanced control system and optimized structure make the operation more reliable and the test data more accurate.

3.The main frame is made of high-strength industrial aluminum profiles, combined with sheet metal parts treated by advanced electrostatic powder spraying and baking paint technology, the appearance is elegant and beautiful, and the sense of technology is full.

4.The built-in sample provides a safer testing process and prevents accidental damage to the machine.

5.Multi-point distribution of emergency brake switches, no matter where the operator is, it is convenient to stop the machine in an emergency. Pad surface durability test:

6.Adopting an independent control system, PLC control alone, combined with a computer display screen, the operation is easy and intuitive, the test process and operating status are clear at a glance, and the number of tests can be set arbitrarily.

7.The unique lifting device is convenient to lift the heavy roller before the test, so as to move it to the mattress testing area, and then lower the roller to fully load its own weight on the mattress surface.

8.The roller group can move up and down freely during the test to adapt to various uneven conditions on the mattress surface.

9.Using advanced photoelectric sensing technology, the starting position of the center line of the mat surface is automatically returned to the original position, the stroke points at both ends are automatically sensed, and the position of the parking area is sensed.

Main Features:

1.Our equipment is controlled by computer, mobile phone control, Internet control, and real-time video monitoring

2.The operating software comes with a test standard program that meets the

requirements, and can be upgraded remotely; the test process can be monitored by no one, and the fault can be automatically alarmed, and the fault can be removed remotely; the remote operation interface of the mobile phone can view the surveillance camera and the safe environment of the laboratory site

3.Multifunctional interface control software, which can control and monitor multiple devices.

4.The control software needs to save the test data of the instrument to the database, which can permanently save and query the historical test data.

5.The laboratory management system can be connected to the computer database on the equipment to facilitate the management of laboratory equipment and data query and filing

6.When no one is in the laboratory, you can enter the device operating system to operate the device through the computer website, QR code, mobile APP, WeChat,

7.If the same operating system is compatible and incorporated into one site to operate the device

8.European standard aluminum profile (thickened)

9.One computer can control and operate all instruments and test items

Standards

GB/T1952.1

(Other test standards can be made according to customer requirements)

Related Products

-

Furniture Testing Equipment

Mattress Hardness Tester TNJ-012-Direct Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Mattress Rollator Tester TNJ-007-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Furniture Testing Machine TNJ-019-Vertical Load Impact Test-Supplier

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Furniture Comprehensive Testing Equipment TNJ-001-Desk ,Chair,Bed,Cabinet-Manufacturer

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Chair Drop Impact Tester TNJ-051-Furniture Drop Testing-Supplier-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Sponge Foam Compression Fatigue Tester -TNJ 028-Supplier

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Sofa Durability Testing Machine TNJ-010-Manufacturer-HUST TONY

Read moreRated 0 out of 5