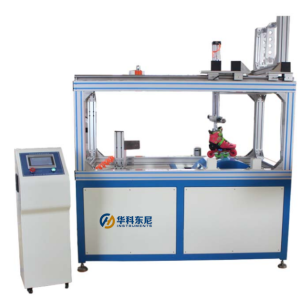

Uv Accelerated Weathering Tester HTE-003-Manufacturer-HUST TONY

Uv Accelerated Weathering Tester

Uv Accelerated Weathering Tester HTE-003 can simulate the harm caused by sun and rain, use fluorescent ultraviolet lamp to simulate sunlight, and use distilled water spray to simulate the effect of rain.

The tested material is tested in a light cycle program at a certain temperature.

Youtube video :Click here

This machine can reproduce the hazards that occur outdoors for months or years in days or weeks.

Types of hazards include: fading, discoloration, loss of light, pink, cracking, turbidity, bubbles, embrittlement, strength, decay and oxidation.

The ultraviolet weathering box can simulate the harm caused by sunlight, rain, and dew, use fluorescent ultraviolet UV lamp to simulate the effect of sunlight, use condensed moisture to simulate rain and dew, and test the test material in a cycle program of alternating light and moisture at a certain temperature.UV weather boxes can reproduce the hazards that occur outdoors for months to years in days or weeks.

Types of hazards include: fading, discoloration, loss of light, chalking, cracking, turbidity, bubbles, embrittlement, strength degradation and oxidation.UV test data can help you select new materials and assess how formulation changes affect the durability of new products.

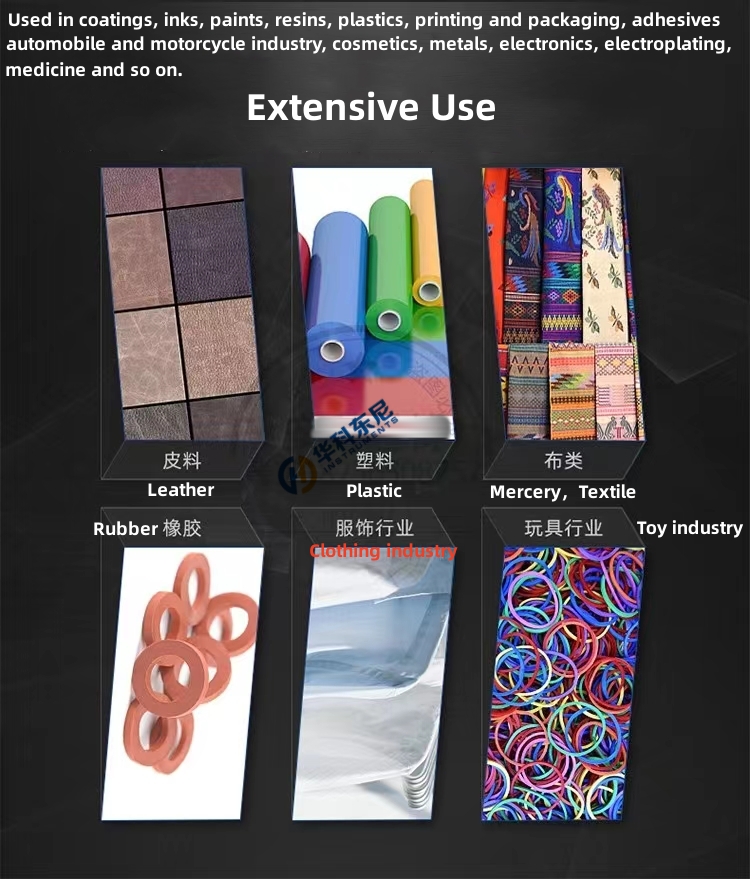

Widely used in coatings, inks, paints, resins, plastics, rubber, printing and packaging, aluminum profiles, adhesives, automobiles, motorcycle industry, cosmetics, metals, electronics, electroplating, medicine, etc.

Technical Specifications

Model | HTE-003 | ||

Internal Box Size | 1140×400×500 mm(W×D×H) | ||

External Size | 1340×630×1400mm(W×D×H) | ||

Temperature Range | RT+10℃~70℃ | ||

Humidity Range | When condensed≥ 75%RH When sprayed≥ 98%RH | ||

Temperature Uniformity | ±3℃ | ||

Temperature Fluctuation | ±0.5℃ | ||

Blackboard Temperature | 50℃~63℃ | ||

Tube Wavelength | UVA-340,Band 315 ~ 400nm Irradiance 0.35 ~ 1.2W/m2 or UVB-313 | ||

Number of Lamps | UVA-340 light tube | 4 Pcs | |

UVB-313 light tube | 4 Pcs | ||

Lamp Power | 60W/ Pcs | ||

Lamp Brand | Philips | ||

Lamp Life | 1600 hours or so | ||

Distance Between Sample and Lamp | 50±3mm | ||

Center Distance Inside the Lamp | 70±5mm | ||

Standard Test Piece Size | 75×150mm | 48 Piece | |

Testing Time | 1~9999 H、M、S adjustable | ||

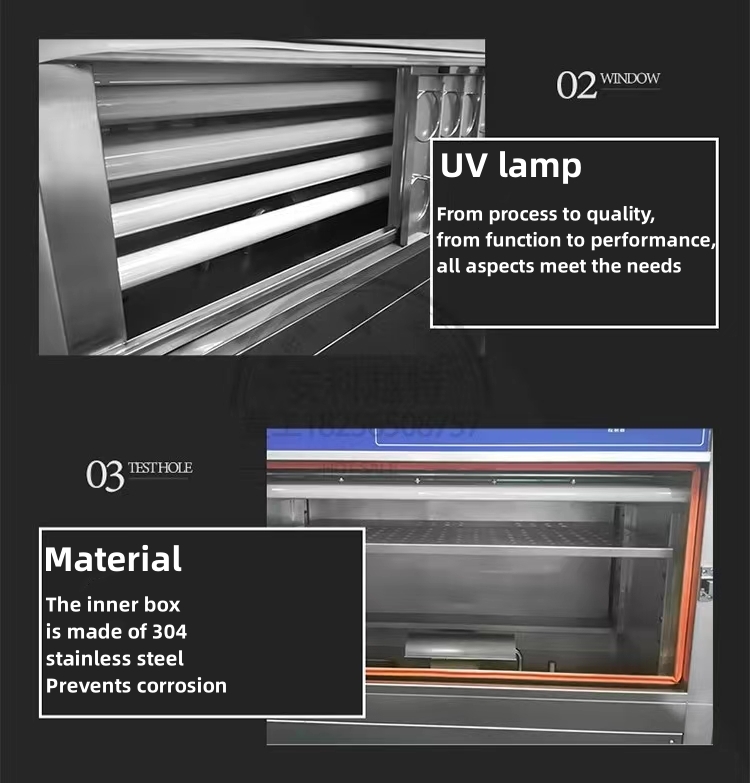

Inner Box Material | SUS304 Stainless steel plate | ||

External Box Material | SUS304 Stainless steel plate | ||

Source of Water | Clean water or distilled water (customer’s own) | ||

Safety Protection System | Line sequence protection, leakage protection, overtemperature protection, abnormal protection | ||

Device Usage Conditions | 1.Please install the waterway in advance, and the water pipe interface is divided into 4 pipes. 2.The equipment placement position should reserve the floor drain or drainage pipe interface, the drainage pipe should be divided into 4 pipes, and the drainage pipe interface should be level with the ground | ||

Power Supply | 220V(single-phase three-wire, a separate 32A air switch, the air switch should have wiring terminals, the power line should be more than 4 square) Frequency: 50HZ Equipment Power: 4.5KW | ||

Environmental Conditions | Temperature: 5 ° C to 30 ° C Relative humidity ≤ 85%RH | ||

Test Condition

1.Sample Mounting Method:The test sample is fixed on the test frame, and when the sample holder is not filled with a fluorescent lamp, the sample holder needs to be filled with a blackboard to keep the inner wall of the test chamber closed.

2.Test Temperature:When the light can be used 50, 60, 70℃ three kinds of temperature, the priority is to use 60℃;The temperature of the condensation phase is 50°C and the tolerance uniformity of the temperature is ±3.

3.Light each condensation cycle:You can choose between 4H illumination, 4H condensation or 8H illumination and 4H condensation

After the first illumination of 400~450H, each row of lamps needs to replace a fluorescent lamp, and other lamps compensate for the loss caused by lamp aging according to the lamp cycle and replacement method.This mode of operation ensures that the service life of each lamp is 1600~1800H.

4.Precautions when replacing lamps:When replacing the lamp, the water tray should be dried and cleaned to avoid the formation of scale.

Test Sample and Performance Evaluation

1.Evaluation of appearance:The coating is mainly the appearance assessment, plastic and rubber can also be evaluated when necessary, the inspection items are mainly gloss, color change, chalking, spots, blistering, cracks and dimensional stability.Instruments should be used as much as possible for quantitative item detection, such as gloss, colorimeter.

2.Evaluation of mechanics and other properties:General rubber materials for tensile strength, elongation, hardness measurement, plastic measurement of impact strength, elongation at break, tensile strength, bending strength, if necessary, can specify other performance test items.

Machine Features

1. The inner tank of the shell is made of high-quality stainless steel material, and the specimen frame is composed of aluminum alloy frame base frame liner and extension spring.

2. The main controller is an intelligent digital display controller, humanized design of the operation method, easy to learn and use.

3. The input adopts a digital correction system, and the built-in thermocouple measurement is accurate and stable.

4. There are position adjustment and AI artificial intelligence adjustment function, a variety of alarm modes.

5. Although ultraviolet (UV) light accounts for only 5% of sunlight, it is the main light factor that causes the durability of outdoor to decrease, because the photochemical reaction effect of sunlight increases with the decrease of wavelength, so when simulating the destructive effects of sunlight on the physical properties of materials, it is not necessary to reproduce the entire sunlight spectrum, and in some cases, only short-wave UV light needs to be simulated.

6. UV lamps are used because they are more stable than other lamps and can reproduce test results better.

7. The use of fluorescent ultraviolet lamps to simulate the effects of light on physical properties such as brightness decrease, fading, peeling, etc., is the best method, most of the number of ultraviolet fluorescent tubes produce ultraviolet light, not visible light and infrared light UVA-340 analog sunlight ultraviolet rays are the best choice.

8. UVA-340 can excellent simulation of the critical shortwave wavelength range sunlight spectrum, that is, the wavelength range of 295 to 360 nm, UVA-340 only produces the spectrum of UV wavelengths found in sunlight.

9. UVB-313 is used to maximize acceleration testing, UVB-313 can provide test results quickly, they use short-wavelength UV rays that are more intense than the UV light waves commonly found on the Earth’s surface today. Although these UV rays, which are much shorter than natural wavelengths, can speed up the test to the greatest extent.

10. The UV weathering test chamber is equipped with ultraviolet irradiation sensor, which is a high-precision photometric control system, which allows users to select the desired illuminance, continuous monitoring of light intensity and fully automatic accurate maintenance.

Structure Declaration

1. The box body is made of CNC equipment, advanced technology, smooth lines, beautiful and generous.

2. The box is made of 1.2CM thick 304SUS high-grade stainless steel.

3. The air duct in the box adopts a single-cycle system and has an imported axial fan, which improves the brightness of the air, the heating ability, and greatly improves the temperature uniformity in the test chamber.

4. Lamps: special ultraviolet lamps, Two rows:8 Pcs, 60W/pcs

5. Lamp life: 1600h (recommended time)

6. Water source and consumption: Tap water or distilled water about 8 liters/day.

7. A total of 8 UVA UV lamps were installed on both sides of the studio.

8. The heating method is inner tank tank heating, fast heating and uniform temperature distribution.

9. Case lid is two-way clamshell type, easy to close.

10. The water level of the inner tank is automatically replenishing, preventing the heating pipe from being damaged by air burning.

11. The specimen holder is made of stainless steel or aluminum alloy.

12. The bottom of the unit is fixed with high-quality PU movable wheels.

13. The drainage system uses a U-shaped sedimentation device to drain water.

14. The surface of the test sample is parallel to the UV lamp plane.

15. The sprinkler system is equipped with automatic sprinkler head and adjustable water pressure.

Temperature Control

UV:

The first-stage optical reaction is not sensitive to temperature changes, however, the speed of the ensuing secondary reaction is closely related to temperature changes.

In general, as the temperature rises, the reaction speed will increase, so in the UV exposure test, temperature control is very important, and it is more important to match the test temperature used in the accelerated test with the maximum temperature encountered by the material in the actual application.

The temperature of the UV process in the device is set to any point of 50 °C ~ 70 °C, depending on the illuminance level and indoor ambient temperature.

The temperature regulation of the equipment is completed by a controller with a microcomputer calculation function to command a series of systems such as air heaters and water heaters in the equipment.

Dampness:

As the temperature increases, the destructive force of moisture on the material increases dramatically.

Therefore, in the wet overmolding, temperature control is the most basic requirement.Furthermore, to produce an acceleration effect, it is necessary to maintain a high temperature environment during wet processes.Therefore, the temperature of the condensation process is set to any point of 40 °C ~ 60 °C

Heating System

1. U-shaped titanium alloy high-speed heating electric heating tube is adopted

2. Temperature control and lighting are completely independent systems

3. The temperature control output power is calculated by the microcomputer to achieve high accuracy and high efficiency power consumption

4.The heating system has an anti-overtemperature function:

(1)The blackboard temperature adopts color touch screen program controller or digital button temperature controller to control heating, the output power is calculated by microcomputer, PID self-tuning, and the monitoring adopts standard PT100 blackboard temperature sensor.

(2)The sink temperature adopts color touch screen program Korean temperature controller to control heating, the sink is located in the lower part of the box, built-in electric water heater.During the test, one of the test sections is the dark condensation process, which requires saturated water vapor to be generated at a higher temperature in the box, and condense dew on the sample surface when the water vapor encounters a relatively cold sample surface.

Safety Protection Device

1. ground protection.

2. Power overload short circuit breaker.

3. Control loop overload, short circuit fuse.

4. Water scarcity protection.

5. overtemperature protection.

Standards

ASTM D4329-2021,ASTM D4587-2011

ASTM D5208-2022,ASTM G154/G53

ISO 4892-3 2016,ISO 11507-2015

ASTM G151-2019.ASTM G151-10 ,SAE J2020 ect.

Application Industry

Related Products

-

Fabric color fastness tester

AATCC Grey Scale For Staining TN-C02B-Supplier

Read moreRated 0 out of 5 -

Fabric color fastness tester

AATCC Gray Scale for Color Change TN-C02A-Supplier

Read moreRated 0 out of 5 -

Leather&Shoes Testing Machine

Roller Skates Durability Testing Machine TL-018-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Leather&Shoes Testing Machine

Shoe Slip Resistance Tester HTF-744-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Textile Testing Instrument

Tumbling Dryer HTF-743-Direct Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Textile Testing Instrument

Fabric GSM Cutter TF-054C-Strict Quality-Supplier-HUST TONY

Read moreRated 0 out of 5 -

Textile Testing Instrument

GSM Circular Cutter TF-054B-Strict Quality-Supplier-HUST TONY

Read moreRated 0 out of 5 -

Textile Testing Instrument

Fabric Sample Cutter TF-054A-Strict Quality-Supplier-HUST TONY

Read moreRated 0 out of 5