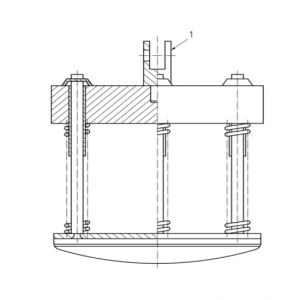

Chair Backrest Durability Testing Machine TNJ-006-Manufacturer-HUST TONY

Chair Backrest Durability Testing Machine

Chair Backrest Durability Testing Machine is to evaluate the ability of the chair back to withstand the fatigue stress and wear that occur as the result of user exerting backward pressure on the chair.

Testing methods:fix chair and impose a poise of 225pounds on the seat surface and keep the tilt mechanism reciprocating movement within its front and back limits for 300000 times at a speed of 10-30cpm.

Standard : ANSI/BIFMA X5.1-2017 , BS EN 1335-1-2020

Technical Specifications

Model | TNJ-006 |

Load cell capacity | 2000N |

Adjustable load direction | 90˚to the chair backrest |

Test speed | 0~50 times/min,adjustable |

Test Times | 0~999 999 times, settable |

Control | PLC touch screen control |

Gas source | ±6kg/m² |

Power | Single phase AC 220V,50/60 HZ 3A |

Dimensions(W*D*H) | 170*68*150 cm |

Net weight | Approx 200kg |

Features

1. Electrically adjustable cylinder output angle.

2. Specimen clamping with no tools required.

3. Humanized operation control, a key to complete the test.

4. Digital voltmeter, voltage monitor, off memory counter, Avoid unravel

5. T-square linear bearing guide screw, stable, smooth

6. Direct manufacturing factory, strict quality, competitive price.

7. One year warranty free.

8. It can be connected to the mobile phone, and the mobile phone can be controlled by the mobile phone.

9. 24-hour monitoring by mobile phone, real-time monitoring of test status.

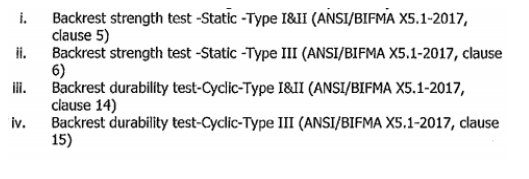

Standards

QB/T2280

ANSI/BIFMA X5.1-2017

BS EN 1335-1-2020

Related Products

-

Furniture Testing Equipment

BIFMA Bag Type Impactor Device TNJ-051-2-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Seat Impactor Device TNJ-051-1-Furniture Impact Test-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Furniture Testing Machine TNJ-019-Vertical Load Impact Test-Supplier

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Bed Comprehensive Tester TNJ-001B-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Furniture Comprehensive Testing Equipment TNJ-001-Desk ,Chair,Bed,Cabinet-Manufacturer

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Chair Drop Impact Tester TNJ-051-Furniture Drop Testing-Supplier-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Furniture Comprehensive Test Machine-For Tables And Chairs TNJ-002B-China Direct Factory

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Cupboard Door Hinge Durability Tester TNJ-026-Supplier-HUST TONY

Read moreRated 0 out of 5