Furniture Testing Machine TNJ-019-Vertical Load Impact Test-Supplier

Furniture Testing Machine TNJ–019

Furniture Testing Machine – Vertical Load Impact Test TNJ-019 for durability on chair seat, table, and bed based on BS EN 1728:2012,BS EN 1730:2012,BS EN 747-2:2012+ A1: 2015,BS EN 1725: 1998

Youtube video : Click here

Technical Specifications

Model | TNJ-019 |

Impact Head Weight | 25Kg |

Impact Height | 80mm~300mm (adjustable) |

Volume (WxDxH) | 265x140x150cm |

Air Source | 7kgf/cm^2 or more stable air source |

Power Supply | 1∮ AC 230V 50Hz 5A |

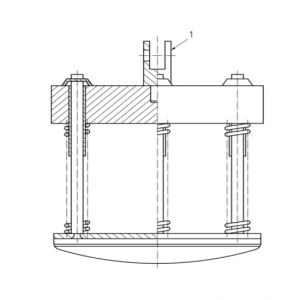

a.Vertical post and cross bar

-To hold cylinder/impactor

b.Pneumatic cylinder

-To hold, release and raise the impactor

-Height: Adjustable height up to 300mm (adjustable)

c.Impactor consists of (refer attachment):

-Circular body –200 mm in diameter,

separated from the striking surface by helical compression springs

and free to move relative to it on a line perpendicular to the plane of the central area of the striking

surface. The body and associated parts minus the springs shall have a mass of (17±0.1) kg and the whole

apparatus including mass, springs and

striking surface shall have a mass of (25±0.1) kg.

-Spring – the nominal spring rate of the combined spring system is (7±2) N/mm and the total friction

resistance of the moving parts is less than 1 N. The spring system shall be compressed to an initial force of (1040±5) N(measured statistically) and the amount of spring compression point to the point where the

springs become fully closed shall be not less than 60 mm.

-Striking surface- shall be a rigid circular object, 200 mm in diameter, the face of which has a convex

spherical curvature of 300 mm radius with a 12 mm front edge radius

d.On/Off switch, machine can be operated manually

Feature

1. European standard aluminum profile. (Thickness and strength 5 times higher than industry)

2. U.S.-origin high-precision force sensors.

3. AirTAC cylinder.

4. Portable magnet retainer.

5. Professional calibration and measure services .

6. Provision of all testing machines and consumables .

7. Direct manufacturer, competitive price, strict quality, high precision, calibration certificate provided.

8.Automatic shutdown when the set number of times is reached, and it can be worked unattended for a long time. Automatic shutdown when the test is complete.

9. After a sudden power failure or artificial shutdown, call or restart again, and continue to run according to the parameters set before the power failure to ensure the continuity and stability of the test and avoid the loss of test data.

Standards

1. Seat impact test (BS EN 1728:2012,Clause 6.24)

2. Vertical impact test (BS EN 1730:2012, clause 6.6)

3. Impact test on bed base (BS EN 747-2:2012+ A1: 2015, clause 5.4.4 )

4. Vertical impact test (BS EN 1725: 1998 , Clause 7.4)

Related Products

-

Furniture Testing Equipment

BIFMA Bag Type Impactor Device TNJ-051-2-Manufacturer-HUST TONY

Read more -

Furniture Testing Equipment

Seat Impactor Device TNJ-051-1-Furniture Impact Test-HUST TONY

Read more -

Furniture Testing Equipment

Furniture Testing Machine TNJ-019-Vertical Load Impact Test-Supplier

Read more -

Furniture Testing Equipment

Furniture Comprehensive Testing Equipment TNJ-001-Desk ,Chair,Bed,Cabinet-Manufacturer

Read more -

Furniture Testing Equipment

Chair Drop Impact Tester TNJ-051-Furniture Drop Testing-Supplier-HUST TONY

Read more -

Furniture Testing Equipment

Furniture Comprehensive Test Machine-For Tables And Chairs TNJ-002B-China Direct Factory

Read more -

Furniture Testing Equipment

Cupboard Door Hinge Durability Tester TNJ-026-Supplier-HUST TONY

Read more