Chair Seat Rotating Testing Machine TNJ-020-Supplier-HUST TONY

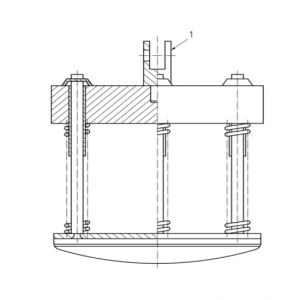

Chair Seat Rotating Testing Machine TNJ-020

Standard :

EN 1728-2012 Section 6.29, 7.11 ,7.13

ANSI/BIFMA X5.1 – 2017 Section 9

EN1335-3 -2020 Section 7.3.3, 7.3.5 method 1

Technical Specifications

Model | TNJ-020 |

Cycle Rate | 5 ~ 15 rotations per minute. |

Rotation Angle | 360 ° |

Loading Weight | 102kg (225lb) |

Counter | 1-999 999 can be set |

Reference Test Method | |

Applicability | This test applies to all types of chairs with a swivel seat. |

Test Feature | Comprehensive testing program, to test the swivel durability of office chair under the cycling pressure. |

Test Procedure | Fix chair on rotary plate, loading 225lbs standard weight |

Rotary plate rotate 120000times in the speed of 5-15CPM, can be adjusted rotation angle by customers. | |

Put the mattress on the test platform, using loading plate to load to the tseting parts. | |

Results Evaluation | After testing, no lose function |

Equipment Performance | PLC control and equip with high power step motor, faces backward smooth, smooth and stable turn back, no impact, truly simulate the actual using status of office chair, humanism operation interface, variety of instruments to monitor, including digital voltage, electricity, speed table, power off memory counter |

Features

1. Specimen clamping with no tools required.

2. Humanized operation control, a key to complete the test.

3. The frame structure design is adopted, and the frame is made of custom-made thickened aluminum profiles. Europe standard aluminum profile(Thickness and strength 5 times higher than industry)

4. Equipped with a high-precision force sensor to sense the force value instantly, each loading group is individually adjusted and controlled, and the loading force value is stable and reliable.

Standards

EN 1728-2012 Section 6.29, 7.11 ,7.13

ANSI/BIFMA X5.1 – 2017 Section 9

EN1335-3 -2020 Section 7.3.3, 7.3.5 method 1

Related Products

-

Furniture Testing Equipment

BIFMA Bag Type Impactor Device TNJ-051-2-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Seat Impactor Device TNJ-051-1-Furniture Impact Test-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Furniture Testing Machine TNJ-019-Vertical Load Impact Test-Supplier

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Bed Comprehensive Tester TNJ-001B-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Furniture Comprehensive Testing Equipment TNJ-001-Desk ,Chair,Bed,Cabinet-Manufacturer

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Chair Drop Impact Tester TNJ-051-Furniture Drop Testing-Supplier-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Furniture Comprehensive Test Machine-For Tables And Chairs TNJ-002B-China Direct Factory

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Cupboard Door Hinge Durability Tester TNJ-026-Supplier-HUST TONY

Read moreRated 0 out of 5