Chair Legs Pressure-Resistant Tester TNJ-003-Manufacturer-HUST TONY

Product Introduction

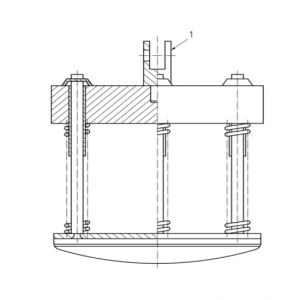

Chair Legs Pressure-Resistant Tester is specially designed for the test of the five-claw seat of the office chair.

The pressure resistance of the five claws is tested by applying pressure to the five claws vertically.

The computer controls the motor as the power source, drives the precision screw to drag the beam to apply pressure downward

Testing purposes:Evaluate the compressive strength of office chair legs, control product quality, find out where defects exist, and provide reference for improvement

Technical specifications

Model | TNJ-003 | |

Capacity | 2000N | |

Max Stroke | 700mm | |

Accuracy of Force to Display | Indicating value ±0.01% | |

Accuracy of Force | Indicating value ±0.05%. | |

Accuracy of Shift | 0.01mm | |

Control Mode | Computer control | |

Special Fixture | Uses to fix five claws. | |

Accessories | Lenovo computers | 1 Set |

HP printer | 1 Pcs | |

Outcome assessment

1. Servo motor control, able to maintain a constant pressure on the chair feet in a state of plastic deformation.

2. Breakpoint automatic shutdown Full computer automatic operation, customers can write test programs by themselves.

3. Computer automatically generates force-time force-displacement curve.

4. The main controller adopts the 21st century 32-bit ARM processor, and the processing speed reaches the level of Pentium-level general-purpose computers. Compared with the traditional 8-bit single-chip microcomputer measurement and control system, the overall performance is greatly improved, the operation speed is faster, and the control accuracy is higher.

5. The core device of data acquisition adopts ultra-high-precision 24-bit AD from the United States, and the sampling rate can reach 2,000 times per second, which can capture the instantaneous change process of power, and the resolution of the whole process is as high as 500,000 divisions.

6. And the latest 6-point calibration technology is used to further improve the accuracy, and the force measurement accuracy standard.

7. Windows standard style, hierarchical operation mode plus detailed help documents and prompts make it the most simple and easy-to-use software in the testing machine industry, and your debugging and software training efficiency will be significantly improved.

8. Using multi-threaded parallel processing technology, the force-displacement, force-time, displacement-time, stress-strain and other curves are displayed simultaneously in real time during the test, and you can switch to the desired curve screen at will and view user settings, etc. Cabinet-type protective structure to ensure safety. Five-star claw damaged automatic stop function, set fixed pressure and time function and other test methods.

Standards

ANSI/BIFMA X5.1- 2011 Section 7

QB/T2280-2007 Section 6.6.8

Related Products

-

Furniture Testing Equipment

BIFMA Bag Type Impactor Device TNJ-051-2-Manufacturer-HUST TONY

Read more -

Furniture Testing Equipment

Seat Impactor Device TNJ-051-1-Furniture Impact Test-HUST TONY

Read more -

Furniture Testing Equipment

Furniture Testing Machine TNJ-019-Vertical Load Impact Test-Supplier

Read more -

Furniture Testing Equipment

Furniture Comprehensive Testing Equipment TNJ-001-Desk ,Chair,Bed,Cabinet-Manufacturer

Read more -

Furniture Testing Equipment

Chair Drop Impact Tester TNJ-051-Furniture Drop Testing-Supplier-HUST TONY

Read more -

Furniture Testing Equipment

Furniture Comprehensive Test Machine-For Tables And Chairs TNJ-002B-China Direct Factory

Read more -

Furniture Testing Equipment

Cupboard Door Hinge Durability Tester TNJ-026-Supplier-HUST TONY

Read more