Salt Spray Tester TNJ-025-1-Corrosion Test-Manufacturer-HUST TONY

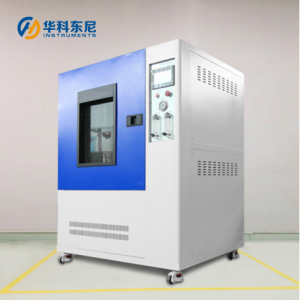

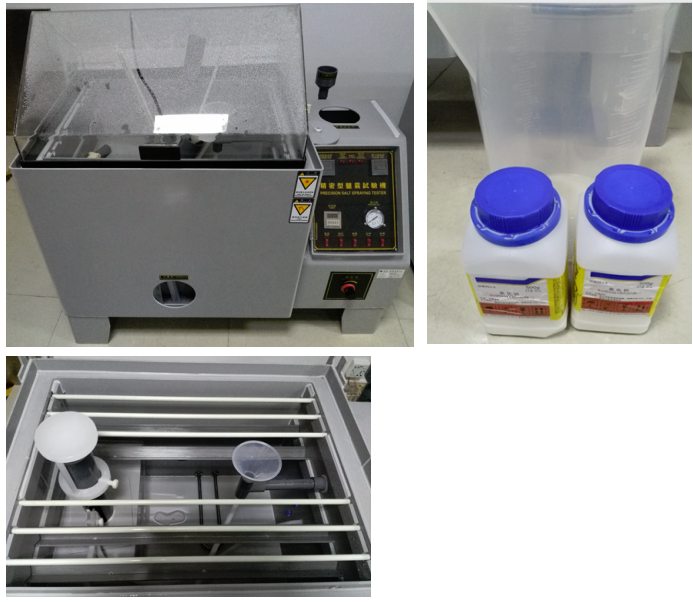

Salt Spray Tester TNJ-025-1

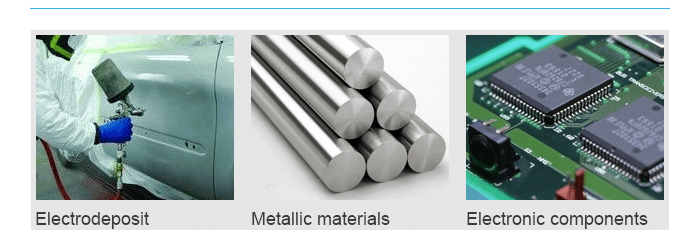

Salt spray tester is used for salt spray corrosion testing of components, electronic components, metal materials and industrial products

Salt spray tester adapted to the surface treatment of various materials, including paint, electroplating, organic and inorganic coating, anode processing, antirust oil and so on, after these anti-corrosive treatment to test the corrosion resistance of their products.

Technical Specifications

Model | TNJ-025-1 | TNJ-025-2 | TNJ-025-3 | TNJ-025-4 | TNJ-025-5 |

Inside Chamber Dimension (WxDxH cm )

| 60x45x40 | 90x60x50 | 120x100x50 | 160x100x50 | 200x120x60 |

Outside Chamber Dimension (WxDxH cm )

| 107x60x118 | 141x88x128 | 190x130x140 | 230x140x140 | 270x150x150 |

Test Chamber Volume | 108L | 270L | 600L | 800L | 1440L |

Brine Tank | 15L | 25L | 40L | 40L | 40L |

Control Method | LED Meter | ||||

Plastic Plate Thickness | 8mm | ||||

Temperature of Test Chamber | Brine test method(NSS ACSS)35℃±1℃ | ||||

Corrosion resistance test method (CASS)50℃±1℃ | |||||

Temperature of Pressure Barrel | Brine test method(NSS ACSS)47℃±1℃ | ||||

Corrosion resistance test method (CASS)63℃±1℃ | |||||

Brine Temperature | 35℃~50℃ | ||||

Brine Concentration | 5% sodium chloride solution concentration or add copper chloride 0.26 grams per liter in the 5% sodium chloride solution concentration. (CuCl2 2H2O) | ||||

Compressed Air Pressure | 1.00±0.01kgf/cm2 | ||||

Spray Volume | 1.0~2.0ml/80cm2/h(gather at least 16 hours, take its average) | ||||

Relative Temperature of Test Chamber | Above 85% | ||||

PH-value | Neutral: 6.5~7.2; Acidic: 3.0~3.2 | ||||

Spray Method | Continuous spray or intermittent spray | ||||

Power Supply | AC220V1Φ10A | AC220V1Φ15A | AC220V1Φ30A | ||

Temperature Range | Laboratory temp. | 35℃- 50℃(can be arbitrarily set) | |||

Pressure barrel temp. | 47℃- 63℃(can be arbitrarily set) | ||||

Temperature Rising Speed | Laboratory | Room temperature →35℃, about 35 minutes | |||

Pressure barrel | Room temperature →47℃, about 15 minutes | ||||

Temp. accuracy | ±1℃ | ||||

Features

1.The whole Salt Spray Tester adopts material of 5mm import gray PVC sheet, Internal adopts advanced band produced three-dimensional reinforcement technology, with strong structure, no deformation, acid and alkali resistance, high temperature resistance, and no aging. It is applied to all kinds of test specifications such as salt spray, copper acetate, etc.

2.Heating method: test room adopts steam direct heating method, temperature rise fast and uniform, reduce the standby time, the heating tube is made from titanium tube with high corrosion resistance.

3.Hopper: 2 built-in spray quantity collection cylinder (only one 60 type ), comparing to the traditional external type, it does not easily break down.

4.Laboratory commodity shelf uses plane dividing shelf, commodity shelf is the ¢10mm toughened glass rod with corrosion resistance. Plastic steel V type shelf and glass rod placing objects make sure the sample 30 degree bevel angle, the angle can be arbitrarily adjusted,the direction of spray falling around is the same as the direction of spay receiving, test piece is set with large quantity.

5.Machine body support: SECC U-bar with angle iron spray paint, four wheel slide and can be pushed for moving( limit use for 120 L type or more than 120 L)

6.Pressure barrel: 2.0MMSUS201 stainless steel seamless welding.

7.Heating delivery: titanium tube used, long service life, high degree corrosion resistance.

8.Salt spray testing machine equipment cover: made of 8MM import transparent acrylic sheets, exquisite workmanship, beautiful appearance.

9.Dual function of over-temperature protection attached, when over-temperature the warning display and cut off the heater power to make sure safe use.

10.Including automatic spray exhausting device. Can clear observe the sample in the test room.

11.Sample supplement jar adopts hidden and water level perspective window attached, it is easy to clean and not easy cracking.

Standards

CNS3627, 3885, 4159, 7669, 8886,

JIS D-0201, H-8502, K-5400, Z-2371,

ISO 3768, 3769, 3770,

ASTM B-117, B-268,

GB-T2423

DIN 50021-SS

Application Industry

Related Products

-

Other Lab Testing Equipment

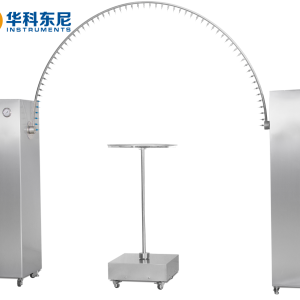

IPX3 IPX4 Oscillating Tubes Rain Tester WT-05-Direct Manufacturer

Read more -

Other Lab Testing Equipment

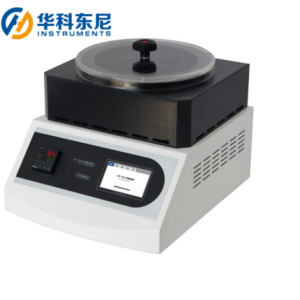

Plastic Film Shrinkage Tester HTZ-031-Factory Direct Manufacturer

Read more -

Other Lab Testing Equipment

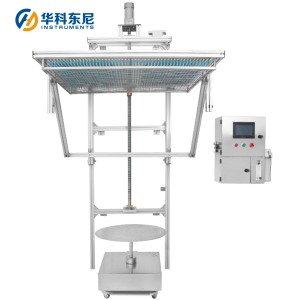

IPX1 IPX2 Drip Rain Test Chamber WT-02-Drip Test-Instrument Manufactuer

Read more